The starter motor is a crucial component in the automotive world, serving as the initial catalyst that brings an engine to life. When you turn the ignition key or push the start button in your vehicle, it is the starter motor that engages and begins the process of cranking the engine. This small yet powerful device is often overlooked until it fails, leading to frustrating situations where a vehicle simply won’t start.

Understanding the starter motor’s role and functionality is essential for any vehicle owner, as it can help in diagnosing issues and ensuring proper maintenance. The importance of the starter motor extends beyond just initiating engine operation; it is a vital part of the vehicle’s electrical system. It works in conjunction with the battery and ignition system to ensure that the engine receives the necessary power to start.

In modern vehicles, starter motors have evolved significantly, incorporating advanced technologies that enhance their efficiency and reliability. As we delve deeper into the components, functions, and maintenance of starter motors, it becomes clear that this seemingly simple device plays a pivotal role in the overall performance of an automobile.

Key Takeaways

- The starter motor is a crucial component in starting a vehicle’s engine.

- Components of the starter motor include the armature, solenoid, and pinion gear.

- The function of the starter motor is to engage the flywheel and crank the engine to start it.

- The starter motor works by drawing electrical current from the battery to generate mechanical force.

- Common issues with the starter motor include worn-out brushes and solenoid problems, which can be addressed through regular maintenance or upgrading to a high-performance starter motor.

Components of the Starter Motor

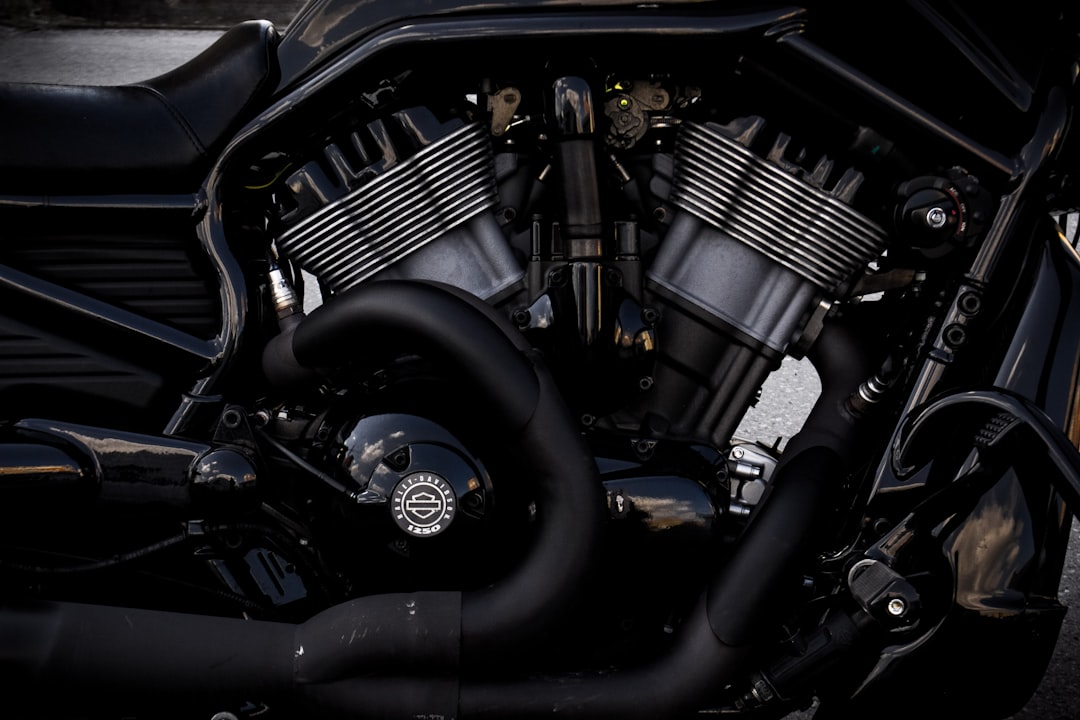

A starter motor consists of several key components that work together to perform its function effectively. At its core, the starter motor includes a housing that encases various internal parts, such as the armature, field windings, and commutator. The armature is a rotating part that generates magnetic fields when electrical current flows through it.

This interaction between magnetic fields creates rotational motion, which is essential for cranking the engine. Another critical component is the solenoid, which acts as a switch to engage the starter motor when the ignition is turned on. The solenoid receives a small electrical signal from the ignition switch, which activates a larger current to flow through the starter motor.

Additionally, there are brushes that maintain contact with the commutator, allowing for continuous electrical flow. The gear mechanism, often referred to as the pinion gear, engages with the engine’s flywheel to initiate cranking. Each of these components plays a specific role in ensuring that the starter motor operates smoothly and efficiently.

Function of the Starter Motor

The primary function of the starter motor is to crank the engine, enabling it to start running on its own power. When you turn the ignition key, electrical energy from the battery flows into the starter motor, activating the solenoid. This action engages the pinion gear with the flywheel of the engine, allowing the starter motor to turn the crankshaft.

The rotation of the crankshaft initiates the engine’s internal combustion process, leading to a successful start. In addition to cranking the engine, the starter motor must also overcome significant resistance from various engine components. For instance, when an engine is cold or has been sitting idle for an extended period, it may require more torque to start due to increased friction and viscosity in the oil.

The starter motor is designed to provide this necessary torque, ensuring that even under challenging conditions, the engine can be started reliably. This capability highlights not only its importance but also its engineering sophistication.

How the Starter Motor Works

| Component | Function |

|---|---|

| Starter Motor | Converts electrical energy into mechanical energy to turn the engine |

| Ignition Switch | Activates the starter motor when turned to the “start” position |

| Battery | Supplies electrical energy to the starter motor |

| Starter Solenoid | Engages the starter motor with the flywheel when the ignition switch is turned |

The operation of a starter motor can be broken down into several stages that illustrate its intricate mechanics. Initially, when you turn the ignition key or press the start button, a small current flows from the battery to the solenoid. This current activates the solenoid, which closes a set of contacts and allows a larger current to flow directly into the starter motor itself.

This surge of electricity energizes the field windings within the motor. As electricity flows through these windings, it generates a magnetic field that interacts with the armature. The armature begins to rotate due to this magnetic interaction, and as it spins, it turns the pinion gear that is engaged with the flywheel.

The rotation of this gear effectively turns over the engine’s crankshaft. Once the engine starts and runs on its own power, a mechanism within the starter motor disengages the pinion gear from the flywheel to prevent damage from continued engagement.

Common Issues and Maintenance of the Starter Motor

Like any mechanical component, starter motors can experience issues over time due to wear and tear or electrical problems. One common issue is a faulty solenoid, which may fail to engage or disengage properly. Symptoms of a failing solenoid include clicking sounds when attempting to start or complete silence when turning the key.

Another frequent problem is worn-out brushes or a damaged armature, which can lead to insufficient power being delivered to crank the engine. Regular maintenance can help extend the life of a starter motor and prevent unexpected failures. One effective practice is to periodically check electrical connections for corrosion or looseness, as poor connections can impede performance.

Additionally, ensuring that your battery is in good condition is vital since a weak battery can place excessive strain on the starter motor during cranking. If you notice any unusual sounds or behaviors when starting your vehicle, it’s advisable to have your starter motor inspected by a professional mechanic.

Upgrading Your Starter Motor

Benefits of High-Performance Starter Motors

High-performance starter motors offer several benefits, including increased torque and faster cranking speeds. This can be particularly useful for vehicles that have been modified for increased horsepower or torque, as it ensures reliable starts under demanding conditions.

Choosing the Right Starter Motor

When considering an upgrade, it’s essential to choose a starter motor that matches your vehicle’s specifications and intended use. This includes selecting a motor that can handle the increased demands of a modified engine, as well as considering factors such as weight and heat dissipation.

Features of Aftermarket Starter Motors

Some aftermarket starter motors come with features such as reduced weight or improved heat dissipation, which can further enhance performance in high-stress environments. These features can be particularly useful for vehicles that are driven in extreme conditions or are used for high-performance applications.

Importance of a Well-Functioning Starter Motor

A well-functioning starter motor is integral not only for starting your vehicle but also for ensuring overall reliability and performance. A malfunctioning starter can lead to frustrating situations where you find yourself stranded or unable to start your vehicle when needed most. Moreover, if left unaddressed, issues with the starter motor can lead to more significant problems within other systems of your vehicle.

In modern vehicles equipped with advanced electronics and systems, a reliable starter motor contributes to seamless operation across various functions. For instance, many vehicles now incorporate features like stop-start technology that relies on an efficient starter motor for quick restarts after stopping at traffic lights or during heavy traffic conditions. Therefore, maintaining your starter motor in optimal condition not only enhances starting reliability but also supports overall vehicle performance.

Keeping Your Engine Running with a Reliable Starter Motor

The starter motor may be a small component in your vehicle’s overall architecture, but its significance cannot be overstated. It serves as the gateway to engine operation and plays an essential role in ensuring that your vehicle starts reliably every time you turn the key or push a button. Understanding its components and functions allows vehicle owners to appreciate its complexity and importance fully.

Regular maintenance and timely upgrades can help keep your starter motor functioning optimally, preventing unexpected failures and enhancing your driving experience. By investing time in understanding this critical component and addressing any issues promptly, you can ensure that your engine runs smoothly and efficiently for years to come.

FAQs

What is a starter motor?

A starter motor is an electric motor that is used to start an internal combustion engine. It is typically mounted on the engine block and is connected to the engine’s flywheel or flexplate.

How does a starter motor work?

When the ignition key is turned, it sends an electrical signal to the starter solenoid, which then engages the starter motor. The starter motor’s gear meshes with the flywheel or flexplate, and when it spins, it turns the engine over, starting the combustion process.

What are the components of a starter motor?

A starter motor typically consists of a motor, solenoid, and a gear mechanism. The motor is responsible for turning the gear, which engages with the engine’s flywheel or flexplate. The solenoid is used to engage the motor and connect it to the battery.

What are the common problems with starter motors?

Common problems with starter motors include worn out brushes, a faulty solenoid, or a worn out gear mechanism. Additionally, a weak or dead battery can also cause issues with the starter motor.

How can I maintain my starter motor?

To maintain your starter motor, it is important to regularly check the connections and wiring for any signs of corrosion or damage. Additionally, keeping the battery in good condition and ensuring proper engine maintenance can help prolong the life of the starter motor.